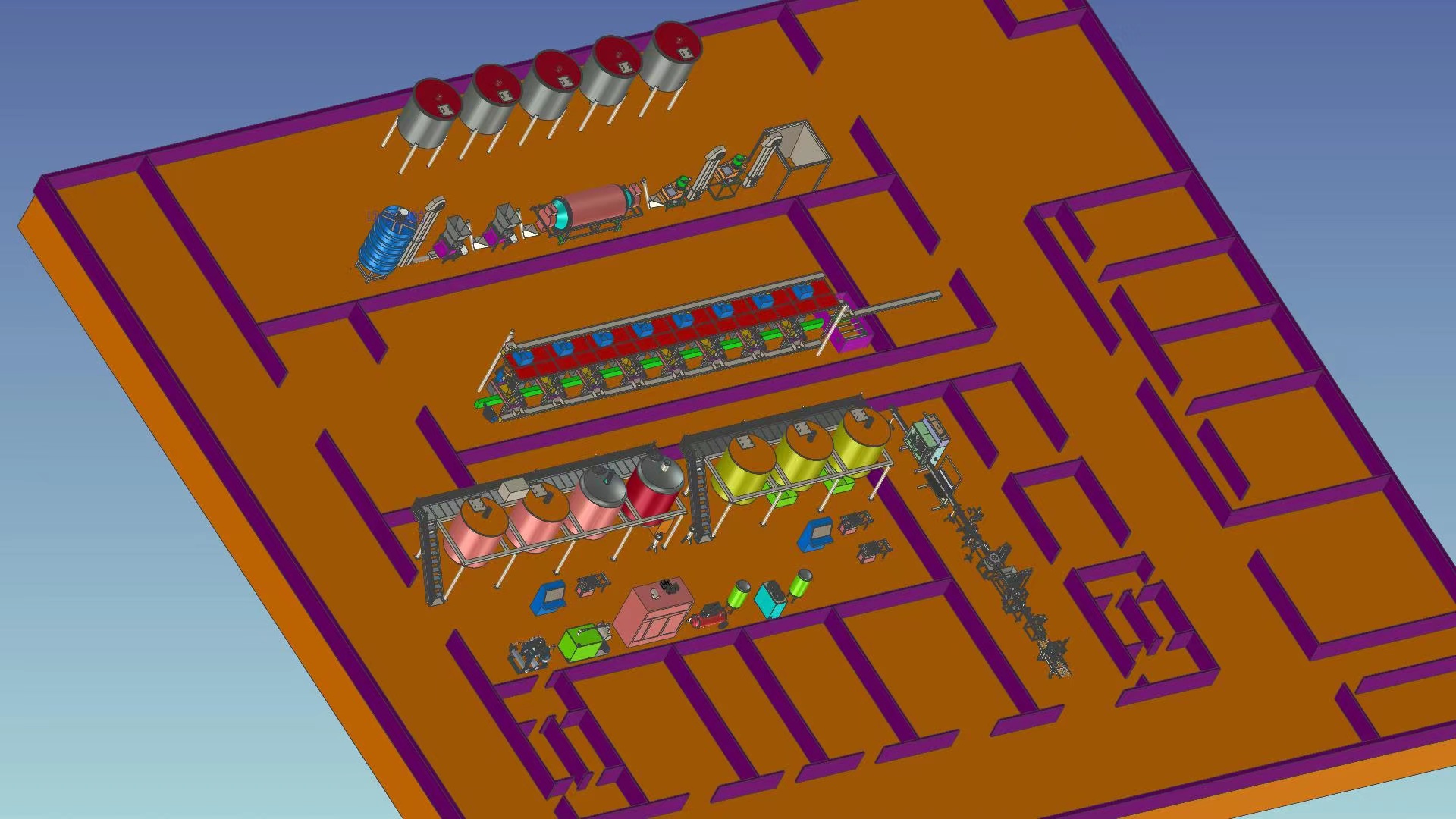

The automated peanut oil filling system by Penguin Group is a technological marvel in the grain and oil industry. It consists of three main functions: filtration, refining, and filling. The filtration function uses advanced filtering technology to remove impurities from the peanut oil, ensuring its high - quality. For example, it can filter out up to 99% of solid impurities with a size larger than 0.1mm, which is crucial for the subsequent refining process.

In the refining process, the system adopts a series of chemical and physical methods to improve the purity and stability of the peanut oil. The filling function is the final step, which accurately fills the refined peanut oil into containers. The system uses high - precision sensors and control systems, with a filling accuracy error of less than ±0.5%, ensuring consistent product quality.

When it comes to material selection, Penguin Group adheres to high - standard principles. The contact parts with the oil are made of food - grade stainless steel, such as SUS304 or SUS316. This not only meets international food safety standards but also significantly extends the service life of the equipment. The average service life of the equipment can reach more than 15 years, and the simple structure design makes maintenance extremely convenient, reducing maintenance time by up to 30% compared with traditional equipment.

Proper operation is the key to ensuring the stable and efficient operation of the automated peanut oil filling system. During the equipment commissioning stage, technicians need to carefully adjust various parameters, such as filling volume, filling speed, and pressure. Through multiple tests and optimizations, the best operating parameters can be determined. For example, by adjusting the filling speed, the production efficiency can be increased by up to 20% without sacrificing filling accuracy.

In addition, coordinating the entire production line is also essential. The filling system needs to be seamlessly connected with other equipment in the production line, such as conveyors and capping machines. By optimizing the production line layout and operation sequence, the overall production efficiency can be improved. For instance, through reasonable coordination, the waiting time between different processes can be reduced by up to 40%, making the production process more streamlined.

Penguin Group understands that different - scale enterprises in the grain and oil industry have different needs. For small family workshops, cost - effectiveness and ease of use are the main concerns. Penguin Group provides a compact and easy - to - operate filling system. This system has a relatively small footprint, which can be easily installed in a limited space. It also has a simple operation interface, allowing even inexperienced operators to quickly master the operation skills. The investment cost of this system is relatively low, which can help small family workshops start their business with a relatively small investment.

For large - scale oil mills, high - efficiency, high - precision, and large - scale production are the priorities. Penguin Group offers a large - scale automated filling system with a high - speed filling function. This system can fill up to 1000 bottles per hour, greatly improving production efficiency. It also has a high - precision control system, which can ensure the consistency of product quality in large - scale production. In addition, the system can be integrated with other advanced management systems, realizing intelligent production and management.

Let's take a medium - sized oil factory as an example. Before using the automated peanut oil filling system of Penguin Group, the factory relied on manual filling, which had low efficiency and high labor costs. The manual filling speed was only about 200 bottles per hour, and the labor cost accounted for about 30% of the total production cost. After implementing the automated filling system, the filling speed increased to 600 bottles per hour, and the labor cost was reduced to about 10% of the total production cost.

In addition, the automated system also significantly reduced production losses. The manual filling process often had problems such as over - filling or under - filling, resulting in an average loss rate of about 2%. After using the automated system, the loss rate was reduced to less than 0.5%, which greatly saved production costs.

The automated filling system of Penguin Group also meets international food safety standards, such as ISO9001. This allows the products of the oil factory to enter the international market more smoothly, enhancing the market competitiveness of the enterprise.

Penguin Group provides high - quality after - sales service and technical support. The company has a professional after - sales service team, which can respond to customers' needs within 24 hours. Whether it is equipment maintenance, parts replacement, or technical training, the team can provide timely and effective solutions.

In addition, Penguin Group continuously conducts technological research and development, and provides free software upgrades for customers' equipment. This ensures that the equipment always maintains the latest technological level and can adapt to the changing market needs.

In conclusion, the automated peanut oil filling system of Penguin Group is a powerful tool for the grain and oil industry to improve production efficiency, reduce costs, and enhance market competitiveness. Whether you are a small family workshop or a large - scale oil mill, Penguin Group can provide you with a customized solution. If you want to upgrade your grain and oil production line and achieve greater benefits, click here to learn more about Penguin Group's automated peanut oil filling system.