In the realm of grain and oil production, the pursuit of efficiency, cost - reduction, and quality control is unceasing. This article delves deep into how Penguin Group's automated peanut oil filling system with filtration and refining functions can revolutionize the production process for enterprises of all scales.

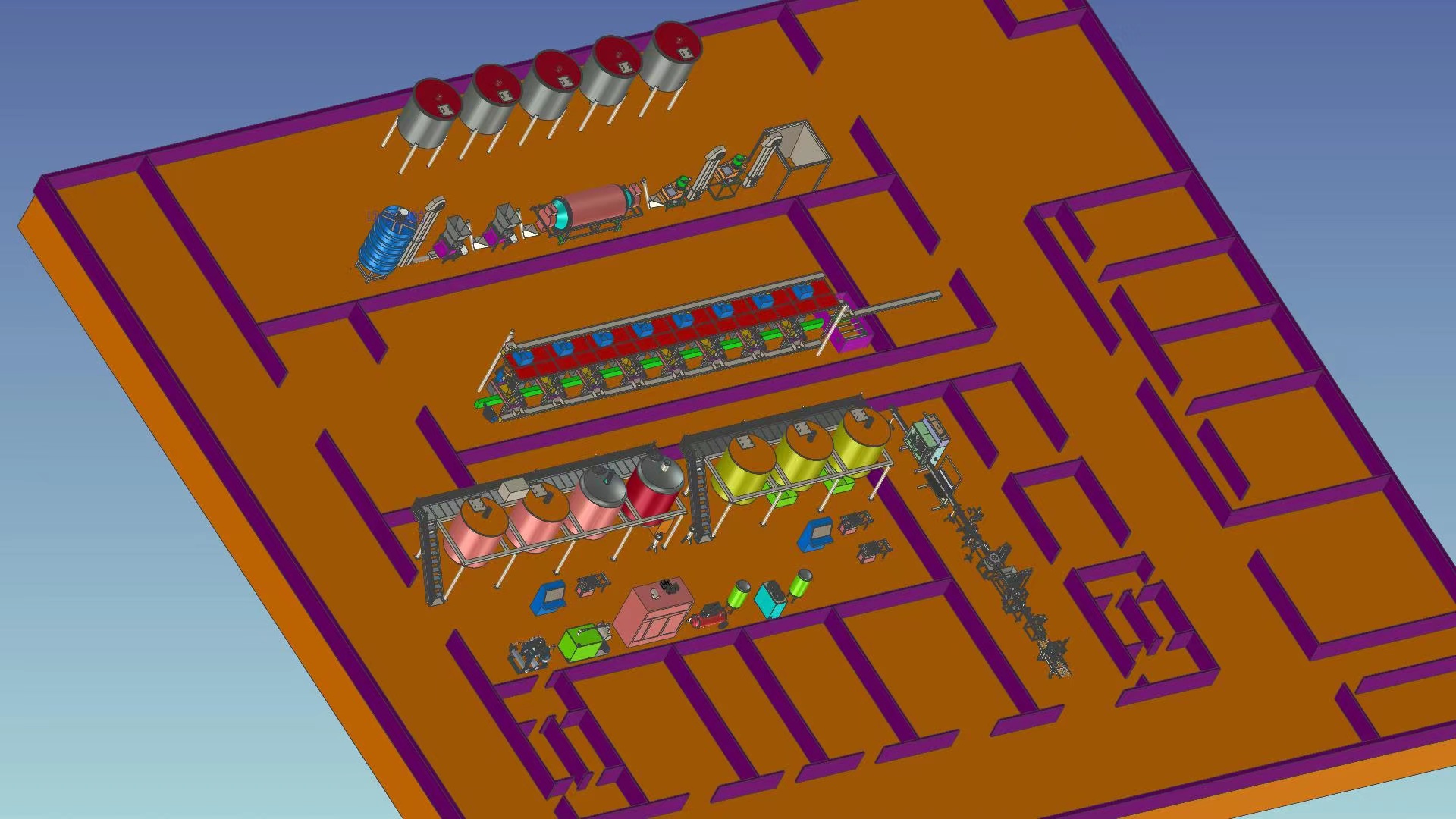

The core of this automated filling system is its integrated design of filtration, refining, and filling. This one - stop solution not only streamlines the production process but also brings significant technical advantages. By combining these three functions, the system can ensure the purity and quality of the peanut oil from the source to the final product. The filtration unit removes impurities, while the refining process enhances the oil's quality, and the filling part ensures accurate and efficient packaging.

The choice of materials is crucial for the longevity and ease of maintenance of the equipment. The system uses stainless steel 304/316 and food - grade seals. Stainless steel 304/316 is highly resistant to corrosion, which can withstand the harsh environment of oil production. The food - grade seals ensure that the oil does not leak and meet the strict requirements of food safety. This combination of materials can significantly extend the service life of the equipment and simplify the maintenance process, reducing the overall cost of ownership.

For operators, mastering the operation skills of the system is essential. The debugging steps need to be carried out carefully to ensure the normal operation of the equipment. Balancing the filling speed and accuracy is a key strategy. A faster filling speed can increase productivity, but it may sacrifice accuracy. Therefore, a proper balance needs to be found according to the specific production requirements. In addition, operators should also know how to deal with common faults, such as blockages in the filtration unit or malfunctions in the filling mechanism.

The system offers customized solutions for small family workshops and large oil mills. Small family workshops may have limited budgets and production volumes, so a more compact and cost - effective configuration can be provided. On the other hand, large oil mills require high - capacity and high - precision equipment. Penguin Group can provide a step - by - step upgrade path for these enterprises, enabling them to gradually improve their production efficiency and quality.

Let's take a look at a real - world example. A medium - sized oil mill implemented this automated filling system and achieved remarkable results. The mill was able to save over $200,000 in labor costs annually and reduce production losses to 0.8%. These data clearly demonstrate the effectiveness of the system in cost - reduction and efficiency improvement.

The system is certified with international standards such as ISO9001, which ensures that it meets the strict requirements of food safety. This not only helps enterprises comply with international regulations but also enhances customer trust. Moreover, Penguin Group provides 7×24 - hour remote technical support and local installation guidance, ensuring that customers can get timely assistance whenever they need it.

In conclusion, Penguin Group's automated peanut oil filling system is a powerful tool for grain and oil enterprises to improve efficiency, reduce costs, and ensure product quality. Are you still relying on manual labor in your filling process? Discover how our system can transform your production!