As a leader or technical supervisor in the edible oil industry, you understand that balancing filling speed with accuracy directly impacts production efficiency, cost control, and product quality. This guide walks you through actionable strategies to optimize both speed and precision in automated peanut oil filling systems, suitable for operations ranging from small family workshops to large-scale oil mills.

Choosing the right material for your filling system's contact parts is foundational. Food-grade stainless steel (usually SUS304 or SUS316) offers corrosion resistance, easy cleaning, and durability that aligns with ISO 9001 international food safety standards. Using such materials not only prolongs machine lifespan by up to 30% compared to conventional metals but also minimizes contamination risks, reducing downtime for cleaning and maintenance by approximately 25%.

Automated systems must juggle the trade-off between throughput (speed) and volume accuracy (precision). Over-accelerating filling can cause overflows and wastage, while overly cautious filling reduces output.

| Parameter | Small Workshop | Large Oil Mill |

|---|---|---|

| Filling Speed (Bottles per Minute) | 30–50 | 100–150 |

| Volume Accuracy (± ml) | ±3 | ±1.5 |

| Optimal Pressure Settings (Bar) | 0.4–0.6 | 0.6–0.9 |

| Cycle Time per Bottle (Seconds) | 1.2–2.0 | 0.4–0.6 |

By fine-tuning parameters such as pneumatic pressure, filling valve opening times, and conveyor speed, you can achieve a near 95%+ volumetric accuracy while maximizing throughput. For example, in a large-scale setting, reducing bottle cycle time from 0.6 to 0.4 seconds may increase speed but can cause spills unless sensor feedback loops are optimized.

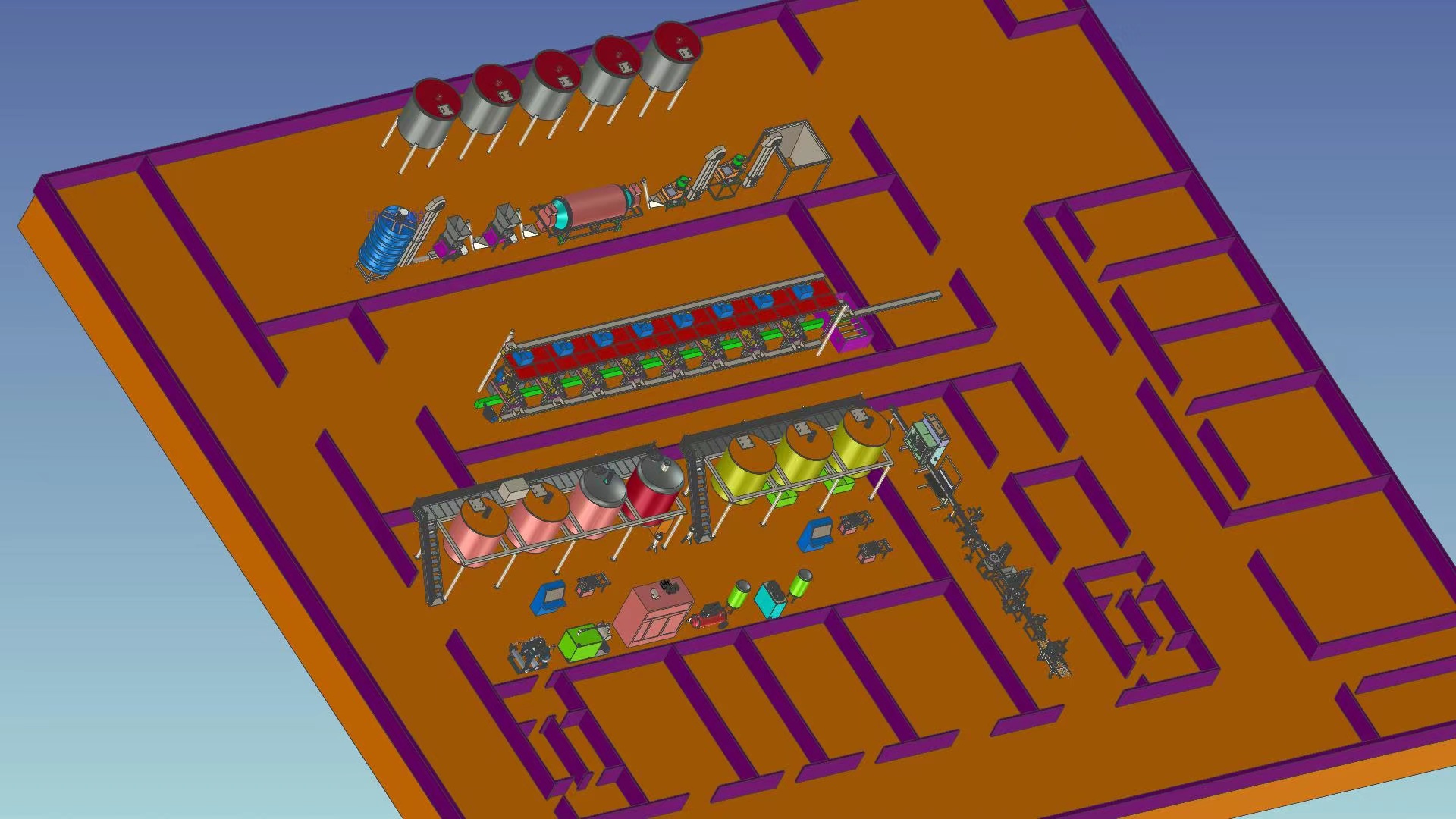

Customizing your automated filling system is key to matching your operational scale and budget:

“Implementing the Penguin Group’s automated peanut oil filling system increased our production efficiency by 35%, cut labor costs by nearly half, and improved consistency to meet export quality standards.” – Zhejiang HuaYou Oil Co.

This feedback echoes the experience of over 200 grain and oil enterprises worldwide who rely on Penguin Group equipment to achieve production excellence, comply with food safety regulations, and maintain competitive edge.

Every automated filling system integrates materials and processes validated against ISO 9001 and related certifications, ensuring:

Such adherence to international standards minimizes regulatory risks and fortifies your brand’s reputation on the global market.

Beyond robust equipment, Penguin Group offers unparalleled after-sales service, including:

With a global footprint across 30+ countries, choosing Penguin Group means your investment is backed by fast, professional, and transparent support wherever you operate.