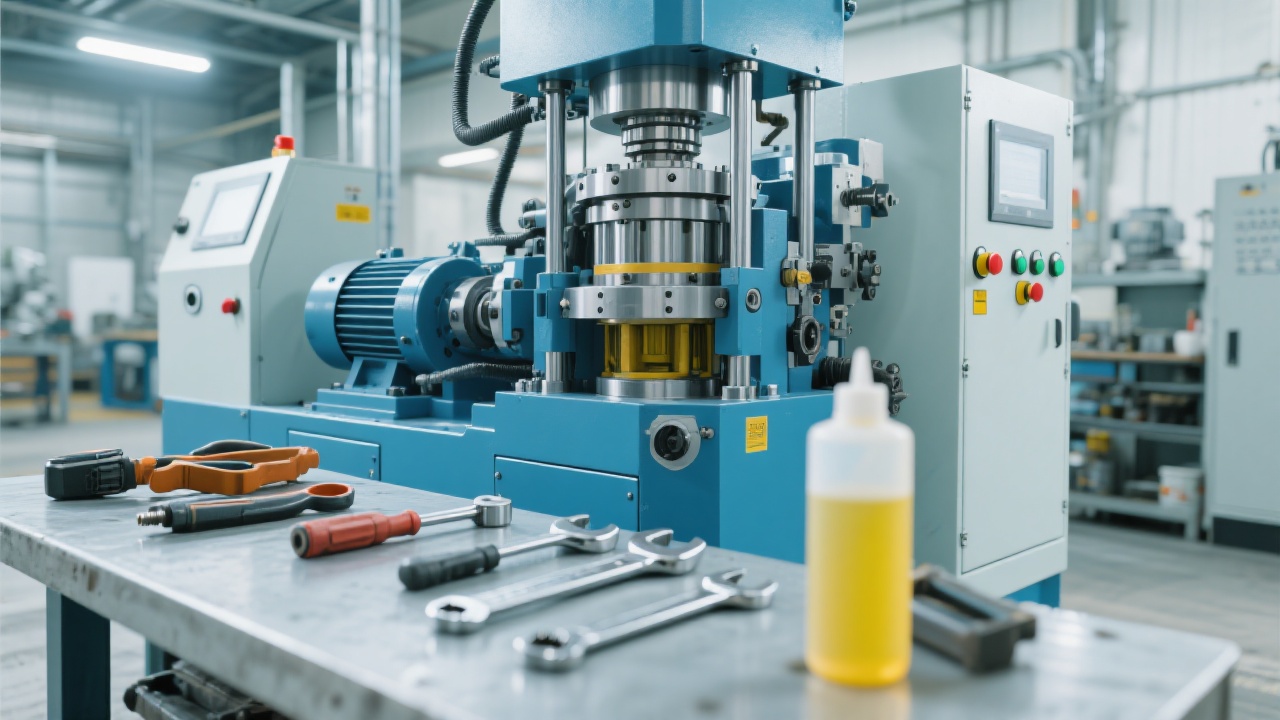

Maintaining a hydraulic press isn’t just about keeping it running—it’s about maximizing uptime, reducing repair costs, and ensuring consistent oil yield in plant-based processing operations. According to industry data from the International Association of Oilseed Processors (IAOP), poorly maintained hydraulic systems account for up to 40% of unplanned downtime in food-grade oil extraction facilities.

Your hydraulic press relies on precise lubrication to reduce friction between moving parts—especially in high-pressure environments like those found in cold-press oil extraction. Experts recommend checking hydraulic fluid levels weekly and replacing filters every 500 operating hours. For example, at a typical 8-hour shift, that means filter changes every 2–3 weeks.

Seals are equally critical. A single worn seal can cause oil leakage, contamination, or pressure loss—leading to efficiency drops of up to 15%. The ISO 15877 standard outlines best practices for sealing materials used in food-grade applications, emphasizing durability under continuous thermal stress. Using NSF-certified seals not only meets compliance but also extends service life by an estimated 30% compared to generic alternatives.

| Task | Frequency | Expected Impact |

|---|---|---|

| Check hydraulic fluid level & color | Weekly | Prevents overheating and cavitation damage |

| Inspect seals for wear or leaks | Bi-weekly | Avoids costly downtime due to pressure loss |

| Clean air filter and check hoses | Monthly | Improves system response time and safety |

Real-world case study: A Turkish olive oil producer implemented this routine across three presses and reduced average maintenance calls by 60% within six months—while increasing daily output by 12%, according to internal records.

Modern hydraulic presses like those from Penguin Group are engineered with robust cast iron frames and modular designs that simplify access to critical components. These features aren't just convenient—they’re part of a broader strategy to minimize labor intensity during servicing. In fact, our field engineers report that such designs cut average technician time per inspection by 35% compared to older models.

What sets us apart? Our commitment to sustainability and reliability goes beyond hardware. Every unit comes with a full-service warranty, remote diagnostics support, and a dedicated technical team available 24/7 via email or chat—because we know that even minor issues can snowball into major losses if ignored.

If you're serious about minimizing operational risk and maximizing ROI on your pressing equipment, start with a structured maintenance plan—and make sure your supplier supports it long-term.

Explore Penguin Group’s Full Line of Maintenance-Friendly Hydraulic Presses →