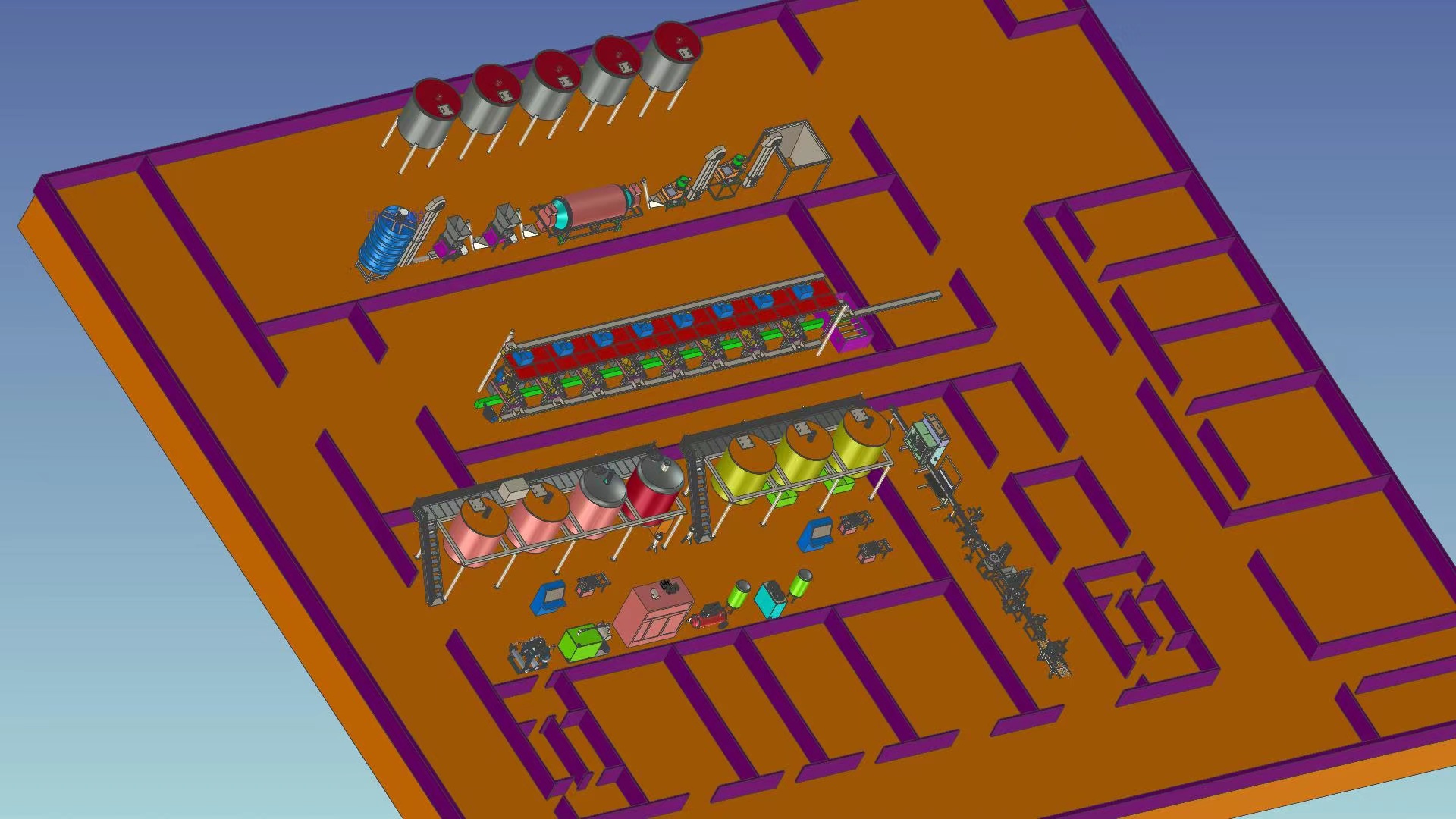

In the evolving landscape of the grain and oil industry, automation has transcended trend status to become a necessity. Rising labor costs and the demand for precision are pushing manufacturers—whether small peanut oil workshops or large-scale refineries—to seek equipment that offers both reliability and regulatory compliance. Penguin Group’s automated peanut oil filling system integrates filtration, refining, and precise filling into one streamlined solution, radically enhancing operational efficiency.

The primary drivers behind adopting automated filling systems are twofold: reducing human error that impacts product consistency and lowering labor costs that account for up to 40% of operational expenditure in traditional production lines. Automated systems like those provided by Penguin Group ensure filling accuracy within ±0.5%, enabling manufacturers to minimize product waste and meet stringent international food safety standards such as ISO 22000 and HACCP.

At the heart of the Penguin solution lies a sophisticated design prioritizing material selection and process optimization:

These technical choices culminate in a filling accuracy that consistently reduces product loss by approximately 3-5% compared to semi-automated alternatives, a considerable saving when scaled to daily production volumes of up to 20,000 liters.

Understanding that each production facility faces unique challenges, Penguin Group tailors its system configuration according to operational scale:

For small workshops, the system can be operational within 2 weeks post-installation, enhancing daily output by 20-30%. Larger facilities experience an efficiency gain of up to 40%, with potential payback periods under 18 months due to labor cost savings and reduced wastage.

One common concern among plant managers is achieving the optimal balance between filling speed and accuracy. Penguin Group’s systems exploit advanced flow meters and feedback loops to maintain a filling speed of 600 bottles per hour, with a volumetric deviation held tightly within ±0.5%. Independent trials confirm that this precision reduces product overfill by 25%, directly decreasing raw material costs.

| Parameter | Traditional Manual Filling | Penguin Automated System |

|---|---|---|

| Filling Accuracy | ±5% | ±0.5% |

| Production Speed (bottles/hour) | 300 | 600 |

| Product Loss Rate | 5-7% | 1-2% |

“After switching to Penguin Group’s automated filling solution, our oil production line saw a 35% rise in efficiency within the first quarter. The system’s precision filling significantly cut wastage, and 24/7 remote support gave us peace of mind throughout commissioning to steady-state operations.” – Director, Sunflower Oil Co.

The transition to automation is more than hardware installation. Penguin Group differentiates itself with comprehensive after-sales care:

These services fundamentally empower manufacturing partners to continuously upgrade their lines with confidence, enabling sustainable growth and competitive advantage.

Does your facility struggle with inconsistent filling, frequent stoppages, or escalating personnel expenses? Embracing automation might be the transformative step you need. Penguin Group’s systems offer scalable options tailored to your operational needs, technical expertise, and budget prospects.